In the world of fashion and apparel manufacturing, no device is more fundamental than the Tech Pack. Often referred to as the “blueprint” of a garment, a tech pack ensures that architects and producers are continuously aligned. But what precisely is a Tech Pack Made Of?

Simply put, a tech pack is a detailed set of documents that portrays each aspect of a garment—from the fabrics and trims used to the sewing details, measurements, and packaging. It disposes of mystery, minimizes blunders, and guarantees that the last item looks and fits precisely as intended.

Whether you’re working on an Activewear Tech Pack, Knitwear Tech Pack, Denim Tech Pack, Loungewear Tech Pack, Swimwear Tech Pack, Sportswear Tech Pack, or a Gymwear Tech Pack, the structure remains steady. What changes are the garment-specific details that reflect the unique needs of each category?

In this direct, we’ll break down precisely what a Tech Pack is Made Of, why it’s imperative, and how it adapts over distinctive apparel lines.

Why Knowing What a Tech Pack Is Made of Matters

Fashion is a high-stakes industry where, indeed, small miscommunications can fetch thousands of dollars. A misplaced crease, an off-base fabric weight, or a miscalculated estimate can lead to wasted tests and missed deadlines. This is why understanding what a Tech Pack is Made Of is critical:

- Prevents Miscommunication – Designers and producers operate in distinctive worlds. A detailed tech pack bridges that gap.

- Saves Costs – Diminishes the number of tests required before the last approval.

- Improves Efficiency – Speeds up generation cycles with clarity and precision.

- Ensures Consistency – Keeps up consistency over sizes, colors, and batches.

- Acts as a Legal Record – Serves as confirmation of unique instructions if debate emerges.

What Is a Tech Pack Made of? (12 Core Elements)

A Tech Pack is Made Of multiple interconnected components. Together, they form a roadmap for accurate garment manufacturing.

Cover Page and Style Information

The cover page gives fundamental identification details so producers know what they are creating. It regularly includes:

- Garment name

- Style number or ID

- Collection/season

- Designer name

- Date of creation and updates

Example: For a Denim Tech Pack, the cover might read: “Men’s Slim-Fit Troubled Jeans – Fashion DNM-2025 – Spring/Summer Collection.”

Technical Sketches (Flats)

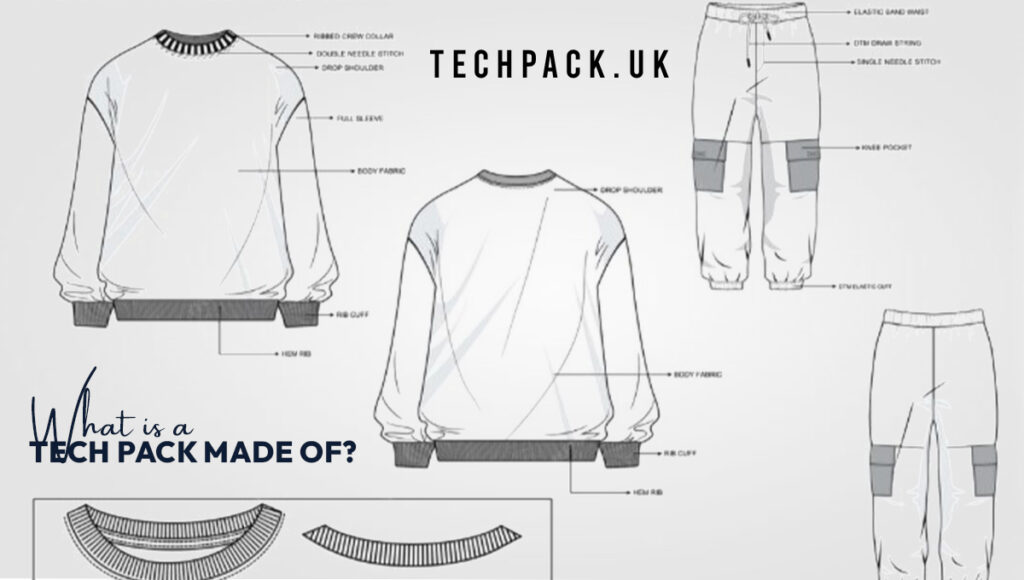

A Tech Pack is Made Of precise sketches that illustrate the garment’s design from all vital points. Known as “flats,” these drawings center on specialized construction, not imaginative flair.

- Activewear Tech Pack: Highlights work boards, intelligent trims, and stash placement.

- Knitwear Tech Pack: Appears with ribbed sleeves, neck area wrapping up, and sleeve drop.

- Swimwear Tech Pack: Shows strap plan, lining, and cut shapes.

Bill of Materials (BOM)

The BOM is the shopping list for garment generation. It indicates each crude fabric required:

- Fabric sort and GSM (grams per square meter)

- Fiber composition (e.g., 90% polyester, 10% spandex)

- Trims (zippers, buttons, drawstrings, labels)

- Color codes and finishes

Example:

- Gymwear Tech Pack BOM may list 280 GSM nylon-spandex, moisture-wicking wrap-up, and a versatile belt with silicon grip.

- Knitwear Tech Pack BOM may incorporate 12-gauge fleece yarn with anti-pilling treatment.

Construction Details

A Tech Pack is made to express information on how the garment is put together. This guarantees fabrication precision.

- Seam types (flatlock, overlock, single-needle)

- Hem wraps up (daze fasten, double-fold hem

- Reinforcement focuses (bear creases, stash edges)

- Stitch thickness and placement

Example:

- Sportswear Tech Pack indicates flatlock creases to diminish friction

- Denim Tech Pack requires chain sewing for toughness and enriching topstitching.

Colorways and Pantone Codes

Color is pivotal in fashion. This area of the tech pack documents:

- Pantone or HEX color codes

- Fabric swatches

- Digital mockups

Example:

- Loungewear Tech Pack: Pastels like dusty pink or sage green.

- Swimwear Tech Pack: Shining neons and tropical prints.

Size Specifications (Spec Sheet)

The spec sheet is regularly the most critical portion of what a tech pack is made of. It characterizes correct garment estimations for each size.

Measurements more often than not include:

- Bust/chest

- Waist

- Hips

- Sleeve length

- Garment length

- Hem and sleeve openings

Example:

- Activewear Tech Pack: Characterizes how compression tights ought to fit over sizes.

- Denim Tech Pack: Records inseam lengths, rise, and thigh measurements.

Grading Rules

Grading rules clarify how measurements scale from one measure to another.

Example:

- Knitwear Tech Pack: Larger-than-usual sweaters must stay proportionate over XS to XXL.

- Gymwear Tech Pack: Compression fits must scale accurately without losing elasticity.

Artwork and Branding

A Tech Pack is Made Of branding information that covers logos, names, and prints.

- Placement diagrams

- Artwork dimensions

- Pantone references

Example:

- Sportswear Tech Pack: Intelligent chest symbol for visibility.

- Denim Tech Pack: Branded calfskin fix, bolts, and embroidery.

Packaging Instructions

This area standardizes retail presentation.

- Folding method

- Tag placement

- Polybag sort and size

- Carton dimensions

Example:

- Swimwear Tech Pack: Waterproof resealable pouches.

- Loungewear Tech Pack: Biodegradable garment bags.

Labeling and Compliance

Labels must include:

- Fiber substance (e.g., 100% cotton)

- Washing and care instructions

- Country of origin

- Compliance marks (e.g., REACH, CPSIA for wear)

Quality Standards

A Tech Pack is Made Of quality rules that guarantee items meet expectations.

- Shrinkage tolerance

- Seam strength

- Colorfastness tests

Case: A Sportswear Tech Pack may request texture withstands 50+ washes without losing elasticity.

Comments and Revision History

Fashion improvement is iterative. This segment archives changes over time, guaranteeing factories continuously reference the most recent form.

Category-Specific Applications of What a Tech Pack Is Made Of

Every apparel category has unique needs:

- Activewear Tech Pack Made of stretch fabrics, breathable mesh, and reflective trims.

- Knitwear Tech Pack: Made of yarn specifications, stitch types, and knitting gauge.

- Denim Tech Pack Made Of washes, rivets, topstitching, and distressing details.

- Loungewear Tech Pack Made of fleece, elastic waists, and relaxed fits.

- Swimwear Tech Pack Made of chlorine-resistant fabrics, linings, and strap adjustments.

- Sportswear Tech Pack Made of moisture-wicking fabrics, reinforced seams, and ventilation.

- Gymwear Tech Pack Made Of compression fits, anti-sweat fabrics, and waistband details.

Common Mistakes in Tech Packs

Even seasoned designers make errors when creating tech packs. Common mistakes include:

- Missing BOM details

- Vague instructions (e.g., “soft fabric” instead of GSM)

- Poorly drawn sketches

- No revision log

- Omitting packaging details

Sustainability and Tech Packs

A modern Tech Pack is Made Of not fair item details but too sustainability objectives. Designers are presently including:

- Recycled fabrics (e.g., reused polyester for activewear, natural cotton for loungewear)

- Low-impact dyes

- Eco-friendly bundling instructions

- Durability prerequisites to decrease waste

Example: A Swimwear Tech Pack may indicate fabric made from reused sea plastics.

Final Thoughts: What Is a Tech Pack Made Of?

A Tech Pack is the backbone of effective garment generation, bridging the gap between plan concepts and wrapped-up items. By clearly characterizing each detail—measurements, materials, sewing strategies, trims, and labeling—a tech pack minimizes blunders, decreases costs, and streamlines communication between architects, producers, and suppliers.

Whether you are making an Activewear Tech Pack, a Knitwear Tech Pack, a Denim Tech Pack, or specialized packs such as Loungewear Tech Pack, Swimwear Tech Pack, Sportswear Tech Pack, or Gymwear Tech Pack, the establishment remains the same: exactness, consistency, and clarity. Each category may request special determinations, but they all depend on the same organized archive to guarantee generation success.

In today’s profoundly competitive design industry, depending on mystery is no longer an alternative. A detailed Tech Pack guarantees your vision is not far caught on but too executed with precision—saving you time, cash, and disappointment. Whether you are a startup brand or a set-up name, contributing to a well-prepared tech pack is one of the most intelligent choices you can make for your design business.

Simply put, a Tech Pack made of exact details and clear communication is the key to turning your inventive thoughts into a wearable reality.

FAQs on Tech Packs: What Is a Tech Pack Made Of?

Q1: Do I need a tech pack for straightforward garments, such as T-shirts?

Yes. A tech pack ensures precision in basic designs indeed.

Q2: How is an Activewear Tech Pack different from a Denim Tech Pack?

Activewear requires extended moisture control details, whereas denim emphasizes washes and stitching.

Q3: Can small brands take advantage of tech packs?

Absolutely—tech packs are imperative for both huge and small-scale production.

Q4: How long does it take to make a tech pack?

Anywhere from 3 days to 2 weeks, depending on complexity.

Q5: What’s the distinction between a spec sheet and a tech pack?

A spec sheet covers estimations as it were; a tech pack covers each generation detail.

Q6: Can manufacturers create tech packs?

Some can, but depending exclusively on producers, danger lose plan control.

Q7: Do tech packs reduce costs?

Yes—by minimizing blunders, sparing on texture squander, and cutting down corrections.